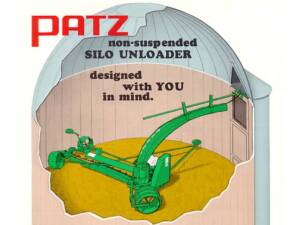

Historic Photo from the Vault – Patz Silo Unloader Testing in 1961

From Day 1, Patz has been committed to designing and manufacturing equipment that saves the user time and money.

Patz was an early market innovator in developing a Non-Suspended, Surface-Driven Silo Unloader that utilized an aggressive ‘Gathering-Chain’. This chain had strategically placed Cutters-and-Claws that could quickly dig out and evenly remove hard-packed  or frozen silage.

or frozen silage.

In 1961, an electrical efficiency test was conducted on the Patz silo unloader at a local Wisconsin farm. The test unit utilized Patz’s innovative gathering chain, equipped with 3 separate electric motors individually metered to measure electrical usage.

The 3-motor test isolated the power demands of the unloader. One motor to measure electrical demands of the drive wheels rotating the unloader around the silo. Another motor powered the aggressive gathering chain which removed hard-packed, frozen silage. And a third motor to measure the electrical demands of the blower that discharged feed to the silo chute.

Test results concluded that the silo unloader’s blower required the greatest energy consumption, while drive wheels for machine rotation required the least. This test proved that the Patz Gathering Chain contributed significantly to the efficiency of the machine. These test results demonstrated that the Patz surface drive design with ‘easy-cutting’ gathering chain was destined to be a success.

Patz partnered with our local Rural Electric Cooperative in 1961 to validate the test results. Shown in this vintage photo conducting the test, left to right, (kneeling) Gaius Nichols of Oconto Electric Cooperative. Standing are Patz employees, John Walker-Sales Manager, Marvin Gusick–Sales Associate, & Harlen Zeitler–Field Technician.

Patz partnered with our local Rural Electric Cooperative in 1961 to validate the test results. Shown in this vintage photo conducting the test, left to right, (kneeling) Gaius Nichols of Oconto Electric Cooperative. Standing are Patz employees, John Walker-Sales Manager, Marvin Gusick–Sales Associate, & Harlen Zeitler–Field Technician.