HOW ACCURATE IS YOUR VERTICAL MIXER WEIGH SCALE?

Do you give much thought to the scale on your vertical mixer? Why is that? Do you have the mindset that the scale is always right? What if it’s not?

The weigh scale on your mixer is important. It measures one of the largest operating expenses on a farm – feed. That small piece of equipment greatly impacts your herd’s health and your bottom line.

Let’s take a closer look at weigh scales and how they relate to your operation.

IMPORTANCE OF WEIGH SCALE ACCURACY ON VERTICAL MIXER

The accuracy of your mixer’s weigh scale is key for several reasons:

Herd Health. Nutritionists formulate TMRs specific to the herd ensuring they’re receiving essential vitamins and nutrients. If the weigh scale is inaccurate, it can lead to an unbalanced diet. If the herd is digesting too much or too little of prescribed nutrients and vitamins, it can impact their health.

Feed Costs & Performance Goals. When feed is the biggest operating expense, even a scale that is just a fraction off can increase your feed expense by thousands of dollars over time. An incorrect scale affects the feed cost and bottom line when feed is overfed, underfed, or left behind. Overfeeding, especially expensive ingredients, can be costly. When ingredients are underfed, valuable nutrients and vitamins may be lacking in the herd’s diet. If the herd is underfed, it can impact the milk revenue. When the diet is unbalanced, it can affect the quality and quantity of the milk production. Lastly, an unbalanced TMR may not be palatable resulting in greater feed refusals.

Keeping your weigh scales calibrated is advantageous in terms of feeding your herd and keeping them healthy. It keeps the TMR balanced, palatable, precise, and consistent.

COMPONENTS OF THE WEIGH SCALE

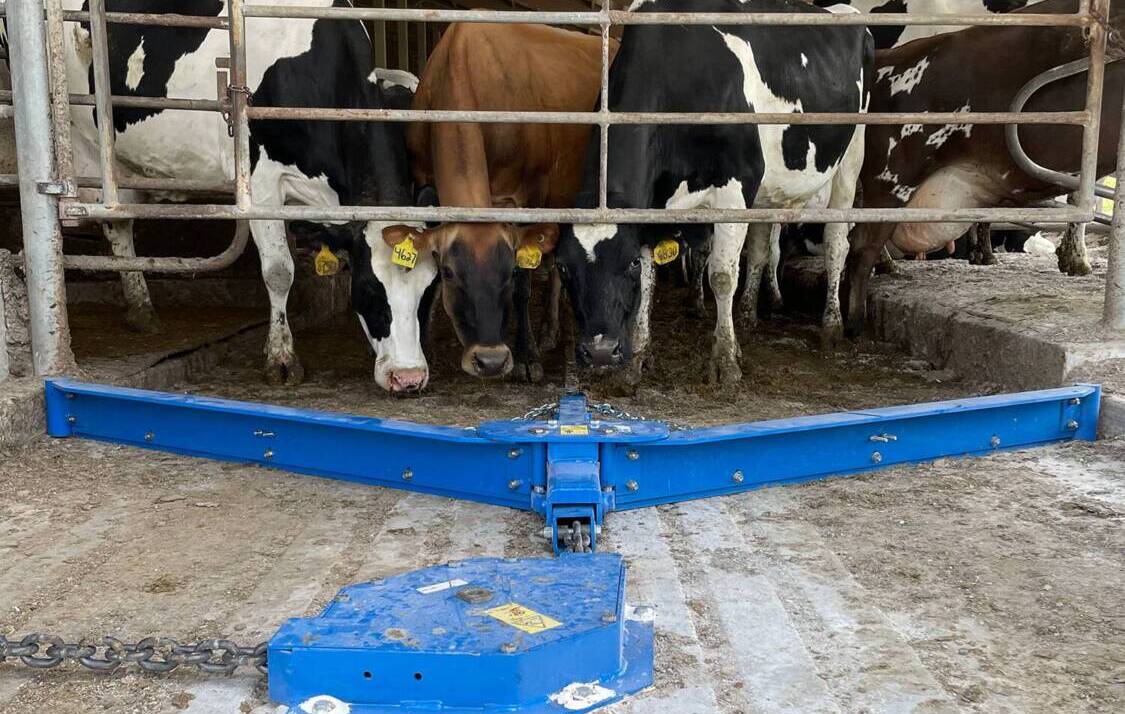

Familiarize yourself with the components of your weigh scale. Knowing the parts and their purpose can help you with maintenance, troubleshooting, and keeping it in optimal working condition. Components typically consist of:

LOAD CELLS (or WEIGH BARS): Depending upon the unit configuration, there are typically 3 or 4 load cells per vertical mixer. The load cells are the foundation of the weigh scale. When the mixer is being loaded, the load cells detect changes in resistance and measure the weight. There’s a direct correlation between the accuracy of the load cells and the weigh scale.

SCALE INDICATOR: This device displays the weight measured by the load cells. Depending on the scale, it can show the operator the total weight or the weight of individual components. Some also have the capability to store multiple rations for different pens.

MOUNTING HARDWARE: The brackets, bolts, and other hardware used to securely attach the weigh scale to the mixer.

JUNCTION BOX: This part collects signals from the load cells and sends them to the Scale Indicator. This is used when the indicator only has 1 port for weigh bars.

SCALE ERRORS

Being aware of the different scale errors that can occur can be helpful in identifying them, correcting them, and keeping your weigh scale accurate. Errors in weight readings can cause:

- under or over feeding

- an unbalanced TMR

- monetary issues

Here are some errors to be on the lookout for:

DRIFT: The scale’s reading gradually changes (or drifts) without altering the weight. Changes in temperature or electronic glitches can cause this to happen.

ZERO ERRORS: The scale does NOT return to zero after the weight has been removed. This can affect readings of future loads making them inaccurate.

HYSTERESIS: This happens when the scale shows a different weight when a load is applied and then removed. Mechanical issues in the loads cells or mounting hardware can be the culprit.

INCONSISTENT SCALE: A consistent percentage is being added or subtracted from the weight. Since it’s a consistent percentage across the board, the ration is formulated correctly. Problems can arise with feed inventories, refusals, and additive costs.

CONSISTENT WEIGHT, ADDED OR SUBTRACTED: A consistent weight is being added or subtracted to each ingredient. This differs from INCONSISTENT SCALE because this is a fixed amount, not a percentage. For example, adding 750 lbs. to an ingredient weighing 2,500 lbs. is very different from adding 750 lbs. to an ingredient weighing 7,500 lbs. Your perfectly calculated ration quickly gets altered. These drastic changes to the ration can affect the health of your herd and your feed inventory.

Scale errors can be kept to a minimum by conducting regular maintenance and calibration on your machine.

MAINTENANCE OF A WEIGH SCALE SYSTEM – SCALE, CABLES, AND BARS

Keeping your vertical mixer weigh scale in optimal condition and accurate is important for multiple reasons. One being that feed is the biggest operating expense on a dairy farm. On top of the cost of feed, there’s the investment in a nutritionist to prescribe a TMR specific to your herd. When your scale is off, the feed you’re delivering to your herd is off. Inaccurate scales impact feed costs, quality and quantity of milk, and other facets of dairy operation. Follow these maintenance recommendations to keep your weigh scale in peak performance:

INSPECTIONS:

Visually inspect the components on a regular basis to find issues before they become problems.

- Check the scale indicator and wire connections. If wires are cracked or pinched, they can give inaccurate or inconsistent scale readings.

- Look under the mixer. Mud and feed debris can pile up on the components and interfere with load cell operation.

- Check the support arms. If rusted or broken, the load cells may not function properly.

- Check the frame on your truck or mixer. If it is broken or flexes improperly, load cells will not ‘feel’ weight correctly.

- Check for any shifts in the frame mounts. Worn collars, broken bolts, worn wheel bearings and other items that may cause the mixer to ride on the frame and not allow a load cell to properly flex.

If you find compromised components, replace immediately.

CLEANING:

Cleaning can remove dirt and debris that can affect scale readings.

- Make sure load cells are free from obstruction and build-up.

- Debris can build up on the components. Keep the mixer and weigh scale free from mud, feed, and other debris.

ENVIRONMENTAL CONTROL:

It’s hard to control the outdoor environment. Be aware of surroundings to minimize harmful environmental conditions.

- Vertical Mixers are operated outdoors in variable conditions. Be responsive to the environmental factors that could impact the accuracy of the scale.

- Farm environments are full of dust, fluids, and other substances that can build-up and impact the scale’s performance. Where the Vertical Mixer is stored can have an impact on accuracy.

- If scale is in a place where there are vibrations, static electricity, or mechanical shock, it can affect the accuracy.

CALIBRATION CHECKS:

Calibrations are done to ensure accurate weight readings. Scheduled calibration checks should be performed on a regular basis. How often you calibrate the scale is dependent on how much its used. See next section, How to Calibrate, for more information.

HOW TO CALIBRATE YOUR WEIGH SCALE:

The short answer to calibrating your weigh scale: Place known weights on the mixer and adjust the scale indicator to match the known weight.

Truck Scale

The easiest way to check mixer’s load weight is on a certified truck scale following these steps:

- Drive onto the truck scale and record the empty weight of the mixer

- Zero out the Scale Indicator

- Fill mixer close to capacity

- Drive back over the truck scale and record weight of fully-loaded mixer

- Subtract the empty weight from the fully-loaded weight. The difference between the two should match the weight on your truck scale indicator.

If a truck scale isn’t available, calibration can be done by hanging known weights off the mixer. The procedure is very similar.

The acceptable industry standard is to have a +/- 1% accuracy.

Manufacturers have set calibration codes based on the mixer and indicator scale model. After verifying the correct code, an authorized dealer can help fine-tune to make the weigh system be as accurate as possible.

SUMMARY

Maintaining the scale mixer is as important as maintaining the vertical mixer. Both of these items are key pieces of equipment in the feeding process. They have a direct impact on whether your TMR is being fed to your herd as intended, which ultimately affects the health of your herd and quality and quantity of your milk production.

Not having a scale that accurately measures weight affects the health of your herd, and that in turn affects your bottom line. Routinely calibrate your vertical mixer weigh scale to manage and maximize the feeding of your herd.