Mastering the Shaker Box Test: Is Your TMR Mixer Performing at Its Best?

Understanding the Key to Proper Feed Particle Size for Dairy Operations

For dairy farmers, the Total Mixed Ration (TMR) is the foundation of herd nutrition and productivity. How do you know if your mixer is delivering consistent, properly-sized feed particles? The answer lies in a simple yet powerful diagnostic tool: the Shaker Box Test. This test helps dairy farmers assess the particle size distribution in total mixed rations (TMR) and determine if their vertical mixer needs an update or upgrade.

What is the Shaker Box Test?

The Shaker Box Te st, also known as the Penn State Particle Separator, is a simple, on-farm method to evaluate particle size distribution in TMR. A series of sieves, or boxes, are arranged in a stack with a solid pan at the bottom. Each box has different-sized perforations. By shaking the feed sample through these sieves, farmers can segregate the feed into various particle sizes and assess its uniformity. A consistent and uniform TMR helps to provide the cows with a balanced diet that promotes digestion and prevents issues such as acidosis.

st, also known as the Penn State Particle Separator, is a simple, on-farm method to evaluate particle size distribution in TMR. A series of sieves, or boxes, are arranged in a stack with a solid pan at the bottom. Each box has different-sized perforations. By shaking the feed sample through these sieves, farmers can segregate the feed into various particle sizes and assess its uniformity. A consistent and uniform TMR helps to provide the cows with a balanced diet that promotes digestion and prevents issues such as acidosis.

How to Conduct the Shaker Box Test

To perform the Shaker Box Test, follow these steps:

- Gather Equipment: Obtain a Penn State Particle Separator.

- Collect a Sample: Take a sample of approximately 1.5 pounds (or 3 cups) of freshly mixed TMR directly from the mixer or feed bunk. Make sure that the sample is representative of the entire batch.

- Weigh the Sample: To ensure accurate results, record the weight of the sample before beginning the test.

- Stack the boxes: Arrange the boxes with the largest screen openings on top, progressing to the smallest, with the solid collection pan at the bottom.

- Shake the sample: Place the sample on the top screen. Shake the entire stack in a specific pattern – typically five times in one direction, then rotate the unit a quarter turn and repeat for a total of eight sets (or 40 shakes). This will allow the particles to pass through the sieves according to their size.

- Weigh & record the contents: After shaking, weigh the feed remaining on each sieve and record the weights. Calculate the percentage of the total sample weight on each level. This will give you the proportion of each particle size in the sample.

How to Interpret the Results

The distribution of particles across the different screens tells you whether your TMR is properly processed:

The distribution of particles across the different screens tells you whether your TMR is properly processed:

**For a typical lactating dairy cow diet, recommended distributions are:**

- Top Screen: Large particles such as forage should constitute a small portion of the diet, typically 2-8% of the total TMR.

- Second Screen: Medium particles, which include a mixture of forage and grains, should make up about 30-50% of the TMR.

- Third Screen: Small particles mostly composed of grains and supplements should account for 30-40% of the TMR.

- Bottom Pan: The finest particles, often seen as powder, should be minimal, around 10-20%, to avoid digestive issues.

If the distribution deviates significantly from these guidelines, it may indicate issues with mixing efficiency or particle size reduction.

Signs Your TMR Mixer Needs Attention

Based on your Shaker Box Test results, here are indicators that your vertical mixer may need updating or upgrading:

- Inconsistent mixing. If the sample from different areas of the feed bunk are getting significantly different results, your mixer may not be providing uniform distribution.

- Too many long particles. An excessive percentage of material on the top screen can indicate worn or damaged knives in your vertical mixer. Cows may sort these longer particles, leading to inconsistent nutrition and potential health issues.

- Too many fine particles. If your bottom pan consistently collects more than 20% of the sample, your mixer may be over-processing the feed, potentially reducing effective fiber and causing digestive issues.

- Difficulty achieving target distributions. If you’ve adjusted mixing times and maintenance but still can’t achieve recommended distributions, your current mixer may not be suited to your specific feed ingredients or volume requirements.

Updating or Upgrading Your Vertical Mixer

If your Shaker Box Test consistently shows suboptimal results, your vertical mixer needs maintenance or an upgrade:

- Update: If the particle size distribution is slightly off, recalibrating the mixer or adjusting its settings may improve performance. Check the condition of knives and augers, as worn components can affect mixing efficiency.

- Upgrade: If results consistently show a poor distribution or the mixer is unable to achieve the desired particle size, it may be time to consider upgrading to a newer model. Newer mixers often offer advanced technology that enhances mixing precision and uniformity.

Modern vertical mixers are designed with feed quality and consistency in mind, offering features that provide more uniform mixing while maintaining optimal particle length.

Upgrading your mixer can lead to significant benefits:

Upgrading your mixer can lead to significant benefits:

- Improved feed conversion efficiency

- Better rumen health and reduced acidosis

- Decreased feed sorting behavior

- More consistent milk production

- Reduced feed waste

- Labor and time savings

Summary

Regular Shaker Box Testing should be part of your feed management routine. It is a valuable tool in the dairy industry, providing insights into the particle size distribution of TMR. By conducting this test, farmers can ensure their cows receive a balanced diet, improving digestion and milk production. Understanding and interpreting the results can guide decisions on whether to update or upgrade your vertical mixer, ultimately enhancing feed quality and animal health. Regular maintenance and evaluation using the Shaker Box Test will help optimize your feed delivery system and support the overall success of your dairy operation.

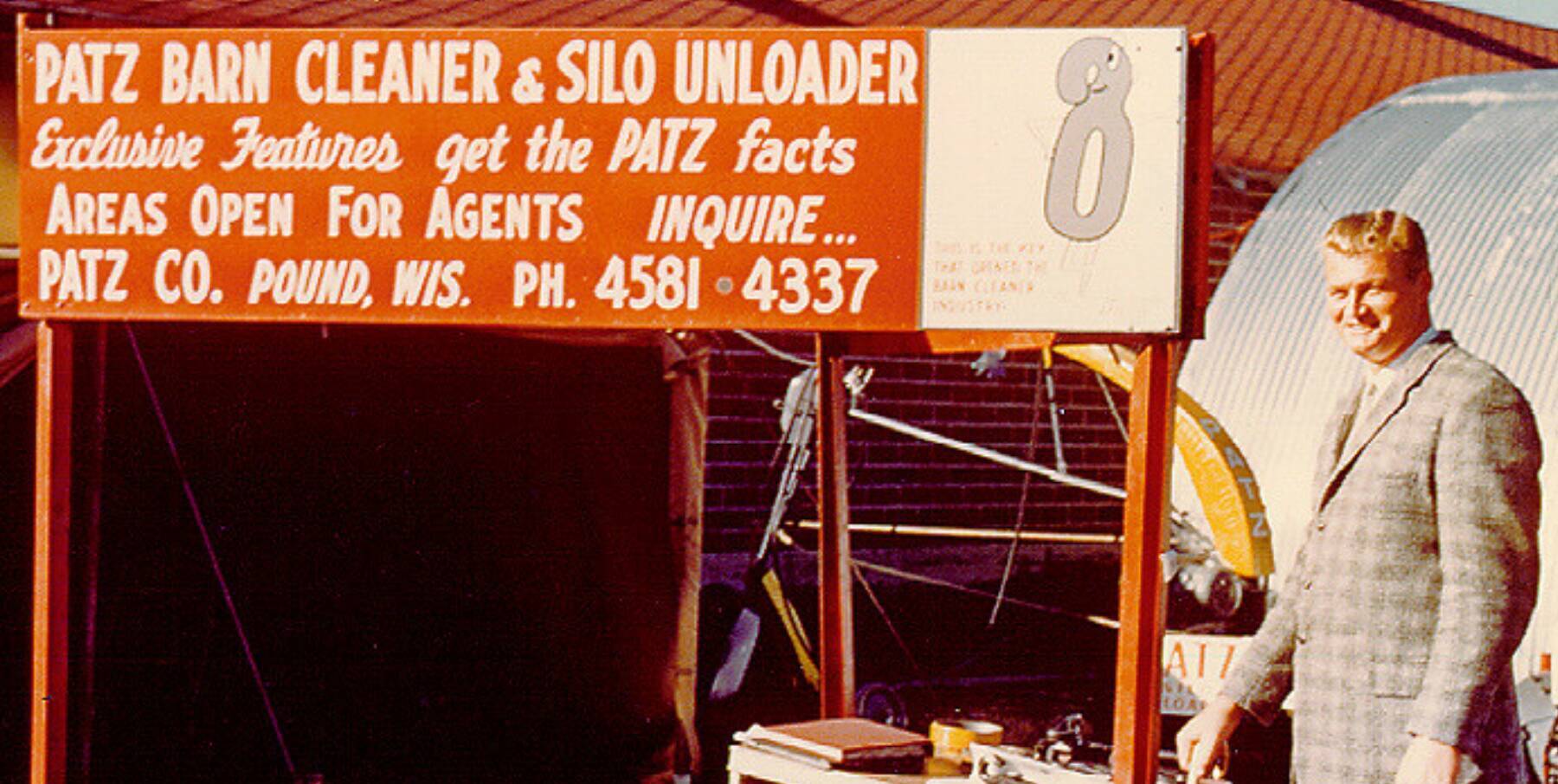

Patz Corporation has been designing equipment to save farmers time and money for decades, with a focus on feed handling systems that deliver consistent results. Their vertical mixer options are engineered to maintain proper particle length while ensuring thorough mixing – critical factors in maximizing your herd’s performance.