Optimizing Feed Efficiency: The Science & Art of Particle Length and Vertical Mixer Knives

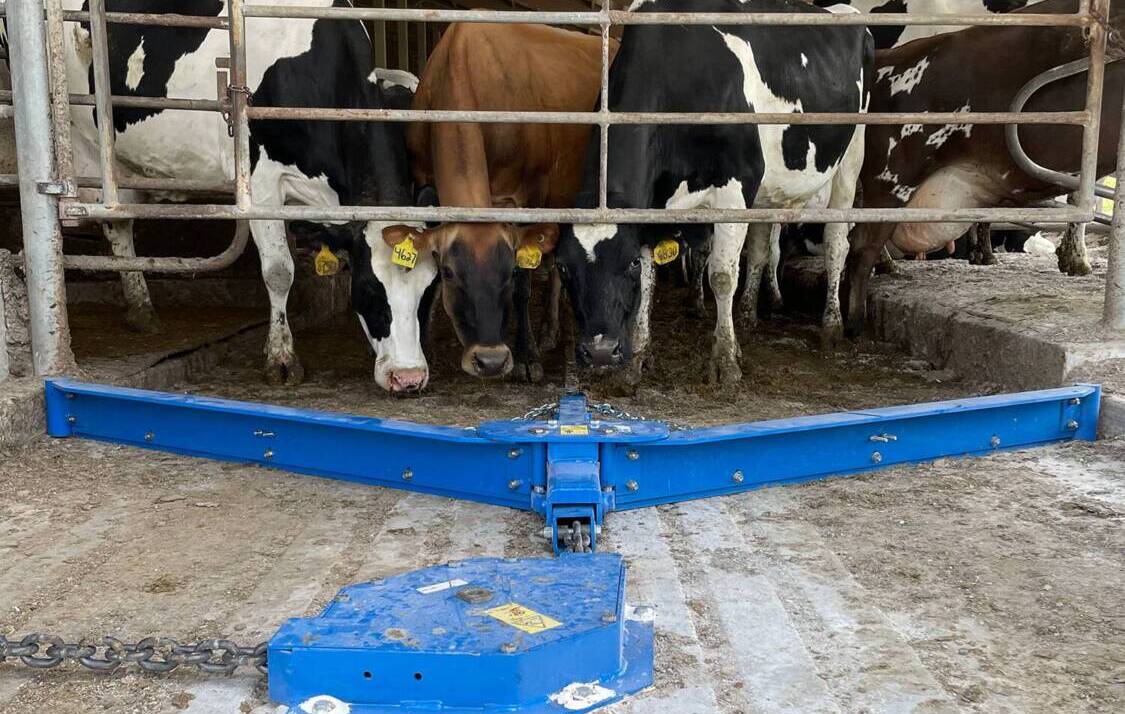

For livestock producers, the quality of feed mixing can significantly impact operational efficiency and animal health. At the heart of this process are vertical mixer knives—components that play a crucial role in achieving optimal particle length for different feed applications. Understanding the proper size, placement, and application of these essential tools can make a substantial difference in your feeding operation.

The Importance of Proper Particle Length

Particle length in dairy feed isn’t just about consistency—it directly affects digestibility, nutrient absorption, and ultimately, milk quality and quantity. Different livestock have different digestive needs, making the right particle size a critical factor in feed efficiency.

As a leader in vertical feed mixers, Patz Corporation, Pound, WI, knows proper particle length ensures animals receive maximum nutritional value from their feed while minimizing waste.

Vertical Mixer Knife Basics

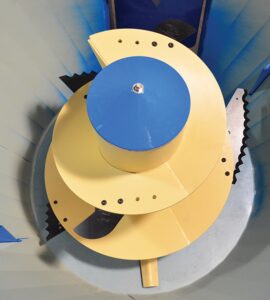

Vertical mixer knives are the workhorses within vertical feed mixers. They are designed to cut and process feed ingredients to achieve consistent, appropriate particle lengths. These knives come in various sizes and shapes allowing for multiple configuration options. Understanding their proper placement and maintenance is key to optimal performance.

Vertical mixer knives are the workhorses within vertical feed mixers. They are designed to cut and process feed ingredients to achieve consistent, appropriate particle lengths. These knives come in various sizes and shapes allowing for multiple configuration options. Understanding their proper placement and maintenance is key to optimal performance.

Recommended Knife Placement

The placement of knives within a vertical mixer significantly impacts mixing efficiency and particle consistency. Like the old adage, baking is a science, cooking is an art, mixer knife setup has been referred to as “more art than science”. Achieving precise particle length in a well-formulated feed ration requires observation and adjustment. Too many knives or too long can overprocess fiber, impede mixing, and waste fuel. Too few knives resulting in excess particle length reduces feed intake, increases sorting and refusals, and decreases feed conversion efficiency.

Typically, vertical mixer knives should be:

- Strategically positioned along the vertical auger

- Spaced to ensure complete coverage of the mixing chamber

- Arranged to create optimal cutting patterns as feed moves through the mixer

Proper knife placement prevents “dead spots” in the mixer where feed might escape processing, ensuring uniform particle size throughout the ration. Not every knife position on the auger needs a knife just because there are holes there. Use only the number and size of knives the ration needs.

Hint: start with knives on every-other position, then add or subtract knives at evenly spaced intervals for desired particle size.

Selecting the Right Knife Size

Knife size selection depends primarily on:

- The type of feed being processed – Roughage-heavy rations may require larger, more aggressive knives. Processed silage or pre-processed dry hay utilize fewer and smaller knives.

- Desired particle length – Different livestock have different optimal particle size requirements

- Mixer capacity – Larger mixers may require more knives to maintain efficiency

Applications for Different Livestock

Dairy Cattle

For dairy operations, particle length significantly impacts rumen function and milk production. Vertical mixer knives should produce a consistent mix with:

For dairy operations, particle length significantly impacts rumen function and milk production. Vertical mixer knives should produce a consistent mix with:

- 8% of the dairy ration should be longer particles (1-2 inches) for proper rumen function, with not less than 2% long hay (≥4 inches) to promote cud chewing

- 30-50% shorter particles for digestibility

- Minimal “sorting” behavior at the feed bunk

Beef Cattle

Beef cattle operations typically benefit from:

- Medium particle length for feedlot rations

- Slightly longer particles for growing cattle

- Consistent mixing to prevent ingredient separation

Maintenance Considerations

The effectiveness of vertical mixer knives depends significantly on their condition. Regular inspection and replacement schedules help maintain optimal performance:

- Check knives for wear and damage regularly

- Replace dull knives promptly to maintain cutting efficiency

- Follow manufacturer recommendations for knife rotation patterns

Remember, dull knives cost fuel while doing NO work!

Time and Labor Savings

One of the primary benefits of properly configured vertical mixer knives is the significant reduction in mixing time and labor requirements. With correctly sized and placed knives, operators can achieve proper particle length in fewer mixing minutes, reducing fuel consumption and equipment wear while improving daily operational efficiency.

Making the Right Choice for Your Operation

Selecting the appropriate vertical mixer knife configuration depends on your specific operational needs. Factors to consider include:

- Primary livestock being fed

- Types of ingredients commonly used

- Desired mixing speed and efficiency

- Overall feeding program goals

Feed ingredients—particularly forages—change year-to-year, season-to-season, and especially cutting-to-cutting. When possible, time mixer knife maintenance with “new feed”. Just as you adjust your ration with routine feed samples, proactively inspect your mixer with every ration change for optimal performance.

To learn more about finding the right vertical mixer knife setup for your specific operation, contact Patz Corporation at 1.920.897.2251, visit our website at https://patzcorp.com, or contact your local, authorized Patz dealer. We have decades of experience in agricultural equipment designed to make farming operations more efficient.