SAND BEDDING: Is it right for your dairy operation?

When it comes to dairy farm management, few decisions impact both your herd’s health and your bottom line quite like bedding choice. Sand bedding has been dubbed the gold standard for dairy cows. Is this gold standard right for your operation? Let’s look at the basic benefits, challenges, and costs associated with sand bedding to help you determine if it’s right for you.

BENEFITS OF SAND BEDDING:

Cow Comfort & Health

Sand bedding is comfortable! Sand is inorganic and conforms to a cow’s body, providing cushioned support that reduces pressure points during rest. This natural material offers traction, or stable footing, and helps cows stand up and lie down more comfortably. Providing a more comfortable bed leads to longer resting times – a critical factor in milk production. Another bonus is that sand does not compact over time, maintaining its supportive qualities throughout use.

Sand produces minimal dust, potentially improving barn air quality and reducing respiratory issues.

Stable Footing & Fewer Injuries

Cows stand up and lie down frequently throughout the day. It’s important to provide them good traction and a stable base. Sand offers that. Having good traction reduces the number of slips and falls; therefore, decreasing the number of injuries to hocks, knees, and other joints. Lameness is decreased (reducing cull rates) and productive lifespans are lengthened (generating more milk).

Udder Health

A significant advantage of sand bedding is its positive impact on udder health. Because sand is inorganic and has excellent drainage properties, bacterial growth is not supported like it is with straw or sawdust. By keeping cows udders clean, it reduces the incidence of mastitis, a costly inflammatory condition that negatively affects milk quality and production. Healthy udders also lower somatic cell counts (SCC) in milk. Lower SCCs typically fetch quality premiums from milk processors.

CHALLENGES

Equipment Wear

Sand particles are highly abrasive and can reduce the lifespan of manure pumps. When handling sand-laden manure, standard manure pumps may experience accelerated wear on components. As pumps wear, operational efficiency may be compromised and more maintenance required.

Manure Management

Sand-laden manure presents unique challenges for storage, handling, and land application. Due to its weight, sand can settle in lagoons and pits. This can reduce storage capacity and require expensive clean-outs. Additionally, sand laden manure applied to fields can potentially affect soil composition over time. When disposing of sand-laden manure, handle with care. Be sure to prevent nutrient runoff to maintain field quality.

Maintenance

All bedding choices require manual labor. When working with sand bedding, keep in mind that stalls need to be leveled and refreshed on a regular basis. Due to the nature of the material, more maintenance may be required.

COSTS: INITIAL INVESTMENT

Facility Modifications

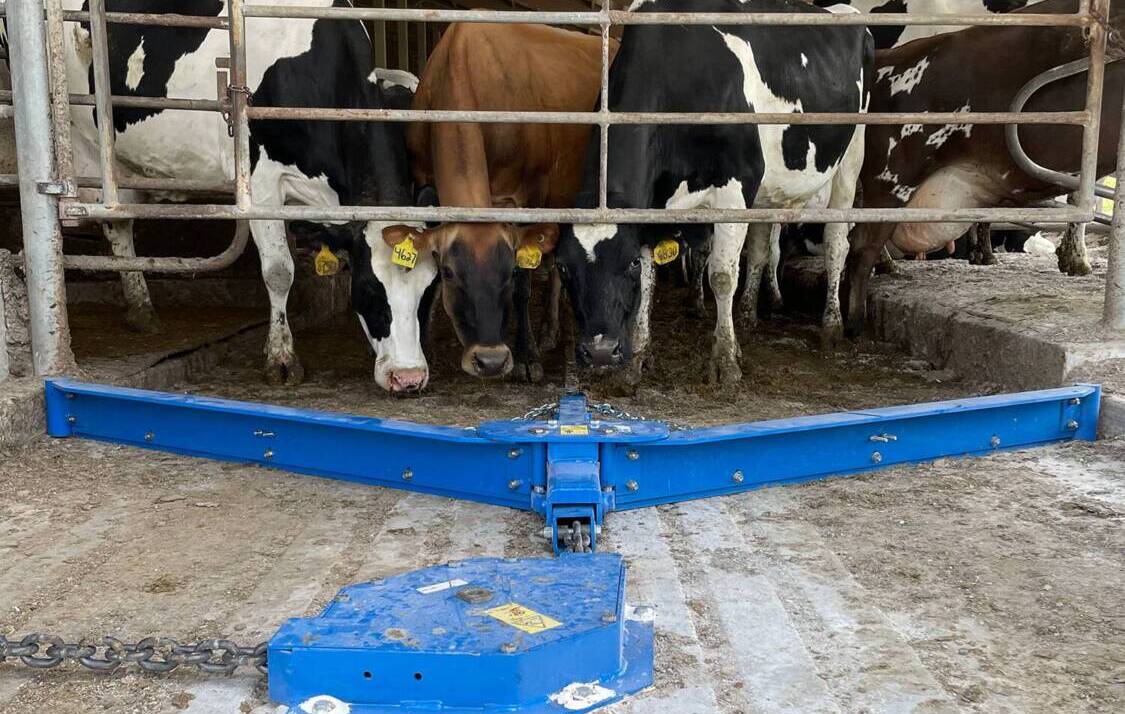

Upgrades to specialized manure handling systems may be necessary to prevent wear and clogging from sand. This equipment can be a substantial upfront investment and may include:

- Sand separation systems

- Modified manure scrapers and pump

- Sand storage facilities

- Equipment for sand reclamation (if implemented)

Initial Sand Purchase

The initial purchase of high-quality sand suitable for bedding can be costly, especially if specific particle size and cleanliness standards must be met. Transportation costs can also be significant depending on the distance from sand sources.

COSTS: ONGOING OPERATIONAL EXPENSES

Sand Rep

Sand needs regular replacement. Depending on your location, quality sand suitable for bedding can cost between $5-20 per ton. A typical free stall barn might require 50-100 pounds of sand per stall initially, with regular additions to maintain proper bedding depth.

Equipment Maintenance

Sand is highly abrasive and accelerates wear on equipment. Pumps, scrapers, and other manure handling equipment typically require more frequent maintenance and replacement when used with sand bedding systems.

Labor Requirements

Managing sand bedding properly requires consistent labor. Manpower is needed for leveling and refreshing of stalls, managing sand tracked into alleys and parlors, and maintenance of equipment.

Water Usage

Some sand management systems require significant water usage for flushing and sand separation, which can increase utility costs and raise environmental considerations in water sensitive regions.

Manure Handling Considerations

Perhaps the most significant cost factor is managing sand laden manure. Sand separation systems, which recover bedding for reuse, represent a substantial investment but can significantly reduce long-term costs. Without separation, sand increases manure volume and may accelerate wear on pumps and equipment. Storage or disposal capacity may need to be increased to handle the volume of sand-laden manure.

IN CONCLUSION

Sand bedding is an investment in the efficiency of your operation as well as the welfare of your dairy herd. Many farmers find the improvements in cow comfort, udder health, milk production, and longevity to justify the additional costs associated with sand bedding. If sand bedding sounds right for your operation, we encourage you to learn more. Evaluate your current bedding situation and consult with experts on how to transition to sand.