Mixer Specifications

| 2000 Series Twin Screw Trailer | 520/520XH | 620/620XH | 740/740XH |

|---|---|---|---|

| Mixer Capacity | 520 ft³ (14.7 m³) |

620 ft³ (17.6 m³) |

740 ft³ (21.0 m³) |

| Capacity with Extensions | 617 ft³ (17.5 m³) |

720 ft³ (20.3 m³) |

845 ft³ (23.9 m³) |

| Max. Load Capacity | 13,000 lbs. (5,897 kg) |

15,500 lbs. (7,031 kg) |

18,500 lbs. (8,391 kg) |

| Height with Singles | 101.75 in. (2.6 m) |

109.25 in. (2.8 m) |

120 in. (3.1 m) |

| Height with Duals | 99.5 in. (2.5 m) |

107 in. (2.7 m) |

117.75 in. (2.9 m) |

| Width | 99.25 in. (2.5 m) |

101 in. (2.6 m) |

103 in. (2.6 m) |

| Length | 290.25 in. (7.4 m) |

292.25 in. (7.4 m) |

296.4 in. (7.5 m) |

| Tractor Horsepower Required | 70 HP | 80 HP | 100 HP |

| PTO Operating Speed | 540 or 1000 RPM | 1000 RPM | 1000 RPM |

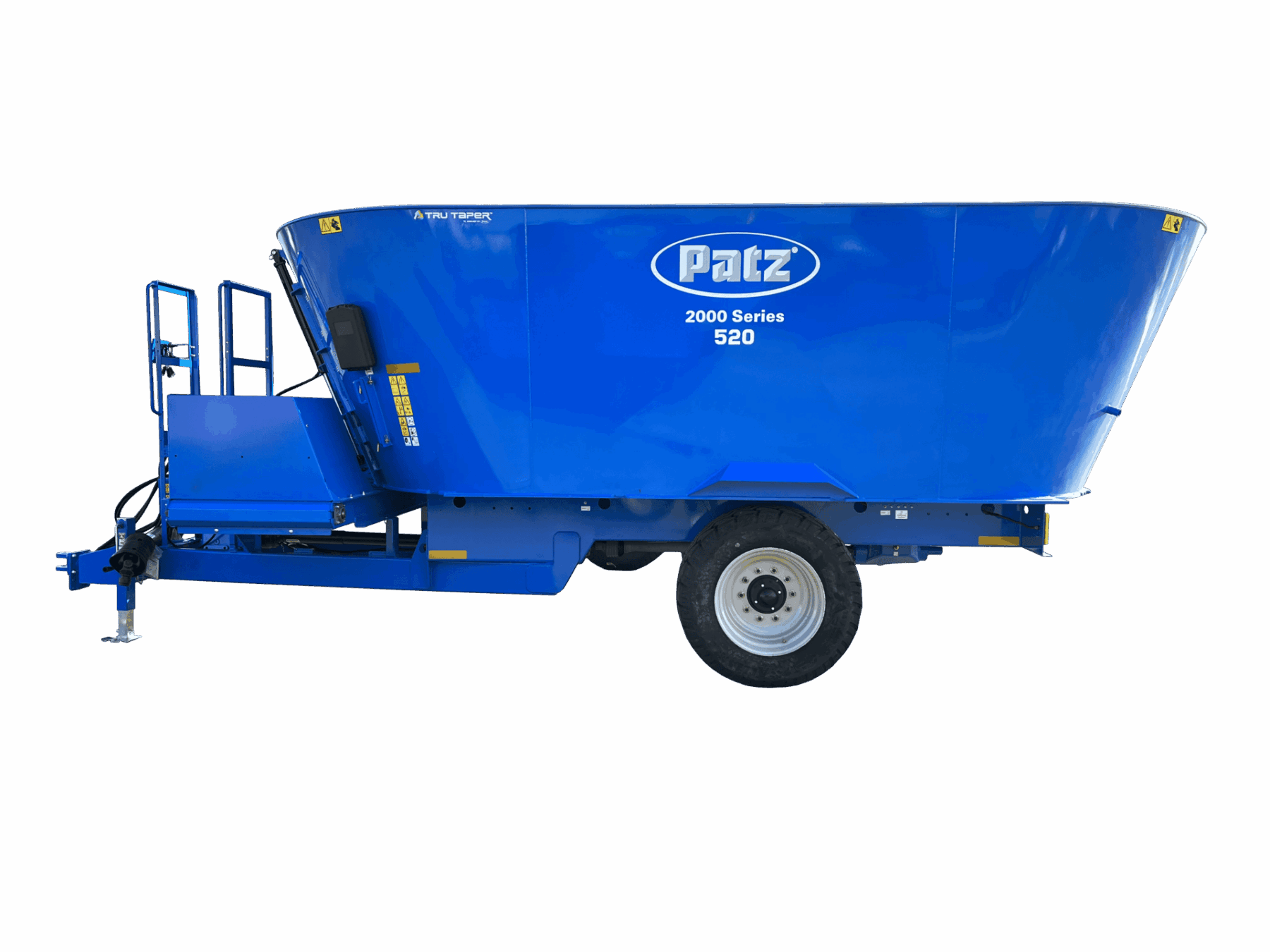

520/520XH

520 ft³

(14.7 m³)

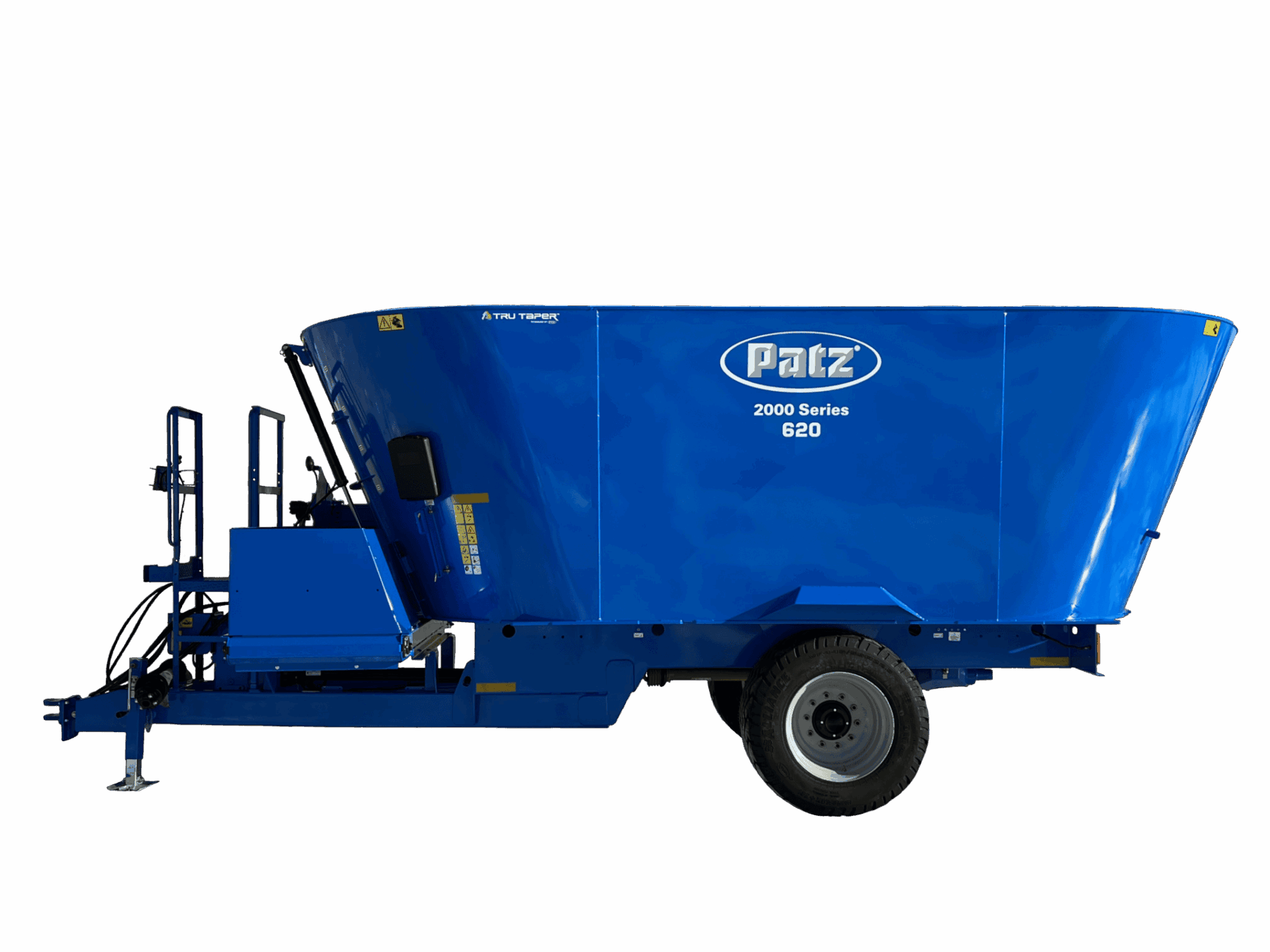

620/620XH

620 ft³

(17.6 m³)

740/740XH

740 ft³

(21.0 m³)

520/520XH

617 ft³

(17.5 m³)

620/620XH

720 ft³

(20.3 m³)

520/520XH

845 ft³

(23.9 m³)

520/520XH

13,000 lbs.

(5,897 kg)

620/620XH

15,500 lbs.

(7,031 kg)

740/740XH

18,500 lbs.

(8,391 kg)

520/520XH

99.5 in.

(2.5 m)

620/620XH

107 in.

(2.7 m)

740/740XH

117.75 in.

(2.9 m)

520/520XH

101.75 in.

(2.6 m)

620/620XH

109.25 in.

(2.8 m)

740/740XH

120.0 in.

(3.1 m)

520/520XH

99.25 in.

(2.5 m)

620/620XH

101 in.

(2.6 m)

740/740XH

103 in.

(2.6 m)

520/520XH

290.25 in.

(7.4 m)

620/620XH

292.25 in.

(7.4 m)

740/740XH

296.4 in.

(7.5 m)

520/520XH

70 HP

620/620XH

80 HP

740/740XH

100 HP

520/520XH

540 or 1000 RPM

620/620XH

1000 RPM

740/740XH

1000 RPM

Applications

Patz Vertical Mixers are used for endless applications in agricultural and industrial setting. Common uses include, but are not limited to:

- Composting

- Recycling

- Municipal Waste

- Livestock & Animal Feed

- Bale Processing

- Offal & By-products

- Mortality / Rendering Poultry & Swine (Disease Mitigation)

- Plastics

Standard Features & Options

DRIVE PACKAGE

Drive package options include: Direct, 2-speed manual, 2-Speed Powershift. Includes oil cooling system.

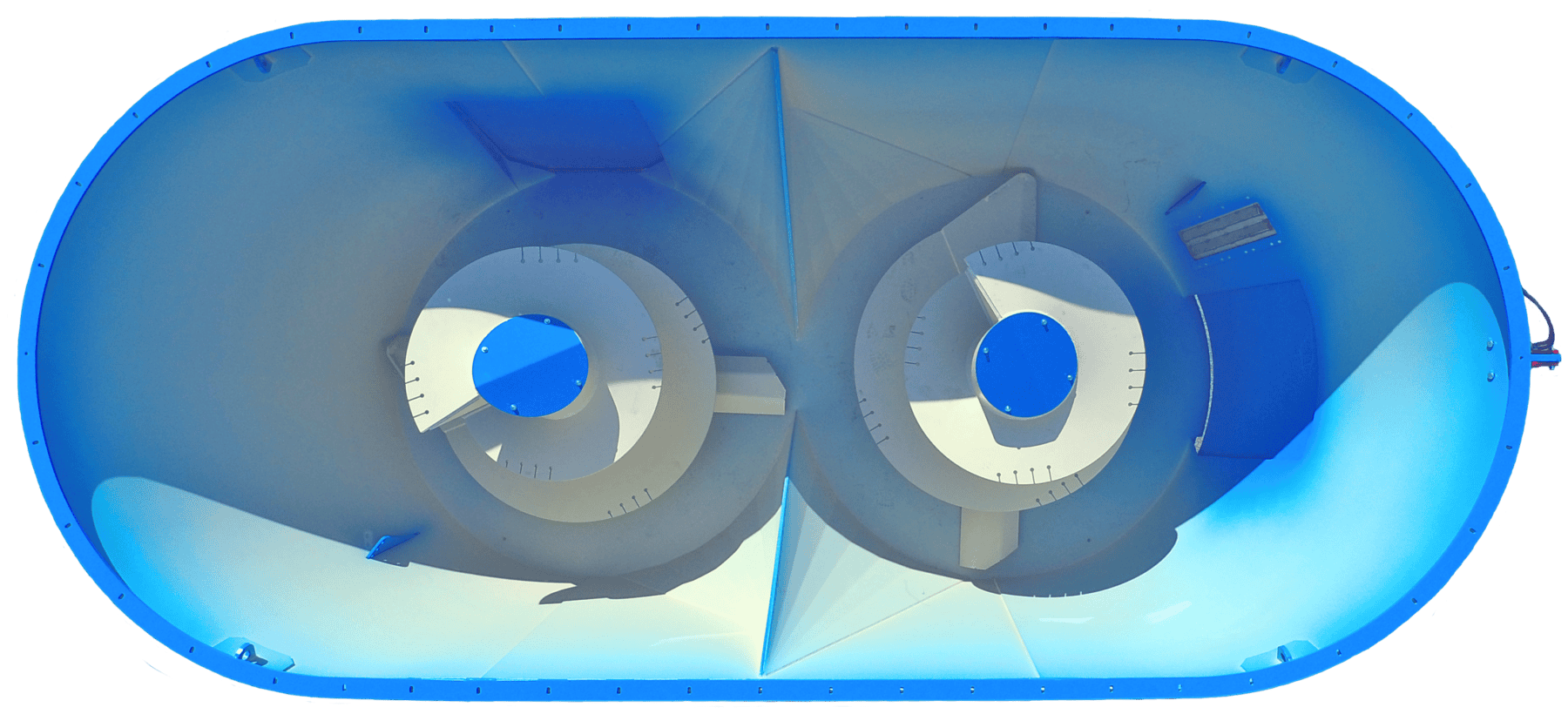

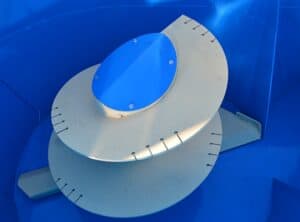

TRU TAPER™ SCREW

Precision-fitted, AR400 – Component vertical screw with welded, shear plow wing creates Patz signature rolling-boil for faster mixing and high-volume feed flow. Standard with dual kicker for fast, even cleanout.

VERTICAL MIXER KNIVES

KNIFE OPTIONS:

Patz vertical screw knife positions are laser cut, ensuring optimal knife placement for fiber processing and torque distribution. Select from 10”, 12”, and 21 ½” serrated knives available in tungsten/carbide coating or AR400 steel to optimize particle length.

Add Patz aggressive RAPTOR® knives for bale processing with patented forward-facing design to keep long hay in the mix.

XH (EXTRA HEAVY) UNITS

(Extra Heavy) units feature a welded steel tub with 3/8″ thick walls and a 3/4″ reinforced bottom.

SIDE EXTENSIONS

Rubber and steel side extensions to extend height of tub 9-1/4″.

DISCHARGE CONVEYOR

Optional discharge conveyor for front door or side discharge openings. Choice of fixed or sliding flat conveyors with right-hand, left-hand, or reversible discharge. Flat with incline and fixed incline conveyors with right-hand or left-hand discharge also available.

TUB MOUNTED MAGNET (OPTIONAL)

Patz patented tub-mount magnet is strong enough to pull tramp metal from the ration while mixing. Encased in stainless steel and tub wall mounted on an easy access hinged assembly for safe, routine removal of errand, ferrous metal.

Contact Your Representative

IA, IL, IN, KS, Lower MI,

MO, NE, Eastern WI

Kevin Habeck

Phone: 920-362-3261

Email: [email protected]

Find your Patz Rep

[display-map id=”4042″]