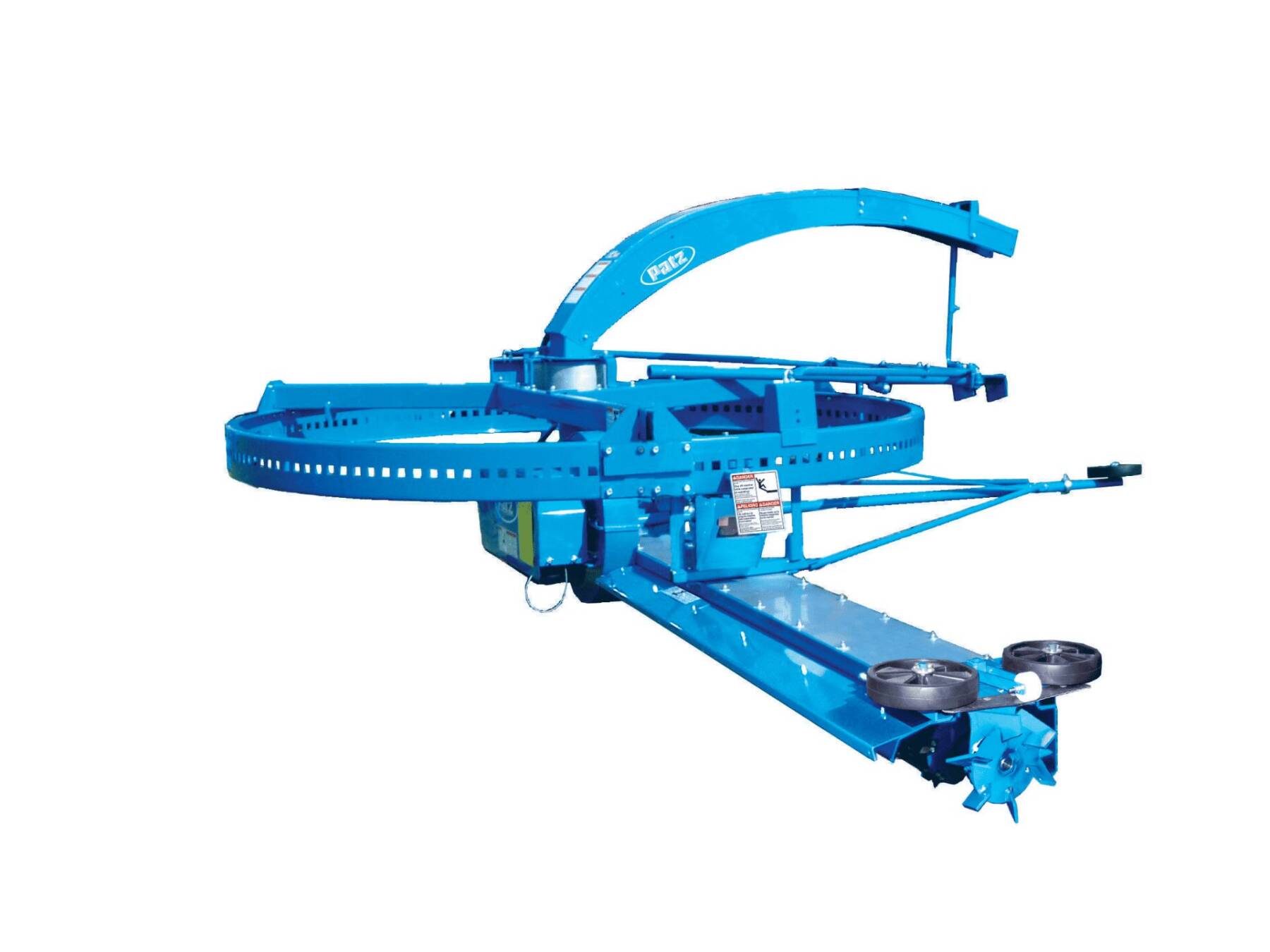

Silo Unloader Specifications

| Single Auger Silo Unloader | A1 Series II |

|---|---|

| Feed Removal | Auger |

| Silo Sizes (Diameter) | 12 – 24 ft. (increments of 2 ft.) (3.7 – 7.3 m) |

| Motor Requirements | 7.5 and 10 HP |

A1 Series II

Auger

A1 Series II

12 – 24 ft. (increments of 2 ft.) ft³

(3.7 – 7.3 m)

A1 Series II

7.5 and 10 HP

Applications

Patz Silo Unloaders are most commonly used in agricultural settings. Product removed from silos include, but are not limited to:

- Haylage

- Corn Silage

- High-moisture Grains

- Frozen Feed

Standard Features & Options

DRIVE RING

This heavy, reversible ring is made from 7-gauge (4.5 mm) thick steel. The 9′ (2.74 m) diameter ring is flanged to the inside for greater strength and is reversible for greater life. Provides maximum stability for proper machine balance in changing silage conditions.

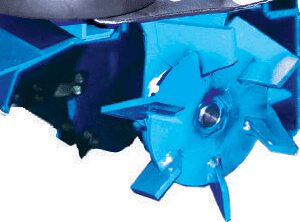

HIGH PERFORMANCE AUGER

Heavy-duty 10” (254 mm) high-capacity auger is made with 1/4” (6.4 mm) thick flighting. Double flighting at the chipper wheel end, and double kickers at the blower end of the auger provide smooth operation while removing the hardest packed and frozen materials.

RING DRIVE GEARBOX

Power to the drive sprocket is transmitted from a rugged ring drive gearbox that is either shaft driven (one motor drive) or motor driven and totally enclosed (two motor drive). The Patz ring drive torque limiter features a farm proven radial-pin design to provide accurate torque release under adverse conditions of hard-packed and frozen silage while protecting the ring and drive system.

WALL WHEELS

Two 10″ (254 mm) diameter heavy-duty polyethylene wall wheels are adjustable for accurate positioning of chipper wheel. An adjustment bolt on each wheel allows for a more precise setting of wheels.

AUTOMATIC LOWERING

SILO UNLOADER SUPPORT SYSTEM

3-POINT SUSPENSION SYSTEM

3-point suspension system keeps unloader level, eliminating the need for counterweights. Choice of suspension arms to fit tripods or hexapods. Optional high clearance suspension arms available for hexapods (16′-24′ models) to add extra feed storage and lift.

DISTRIBUTOR SUPPORT BOARD

Contact Your Representative

IA, IL, IN, KS, Lower MI,

MO, NE, Eastern WI

Kevin Habeck

Phone: 920-362-3261

Email: [email protected]