Belt Conveyor Specifications

| Belt Conveyor | 1205 | 1605 | 1608 | 2405 | 2410 | 3605 |

|---|---|---|---|---|---|---|

| Direction | 1-way | 2-way | 1-way | 2-way | 2-way | 1-way |

| Belt Width | 12″ (305mm) | 16″ (406mm) | 16″ (406mm) | 24″ (610mm) | 24″ (610mm) | 36″ (914mm) |

| Belt Speed | 65-370 FPM | 65-370 FPM | 260-390 FPM | 65-370 FPM | 95-325 FPM | 65-370 FPM |

| Overall Length | 10′ – 160′ (3.05 – 48.77m) | 10′ – 120′ (3.05 – 36.58m) | 10′ – 200′ (3.05 – 60.96m) | 10′ – 120′ (3.05 – 36.58m) | 10′ – 400′ (3.05 – 120.92m) | 10′ – 120′ (3.05 – 36.58m) |

| Full Load Capacity | 3,700 lb/min | 3,700 lb/min | 3,900 lb/min | 3,700 lb/min | 3,250 lb/min | 3,700 lb/min |

1205

1-way

1605

2-way

1608

1-way

2405

2-way

2410

2-way

3605

1-way

1205

12 in.

(305 mm)

1605

16 in.

(406 mm)

1608

16 in.

(406 mm)

2405

24 in.

(610 mm)

2410

24 in.

(610 mm)

3605

36 in.

(914 mm)

1205

65 – 370 FPM

1605

65 – 370 FPM

1608

260 – 390 FPM

2405

65 – 370 FPM

2410

95 – 325 FPM

3605

65 – 370 FPM

1205

10 – 160 ft.

(3.05 – 48.77 m)

1605

10 – 120 ft.

(3.05 – 36.58 m)

1608

10 – 200 ft.

(3.05 – 60.96 m)

2405

10 – 120 ft.

(3.05 – 36.58 m)

2410

10 – 400 ft.

(3.05 – 120.92 m)

3605

10 – 120 ft.

(3.05 – 36.58 m)

1205

3,700 lb/min.

1605

3,700 lb/min.

1608

3,900 lb/min.

2405

3,700 lb/min.

2410

3,250 lb/min.

3605

3,700 lb/min.

Applications

Patz Conveyors and Feeders are commonly used for moving material in agricultural and industrial settings. The uses are endless! Applications include, but are not limited to:

- Livestock Feed

- Lumber Mills

- Vegetables

- Fish Cleaning

- Digester

- Big Box Stores

Standard Features & Options

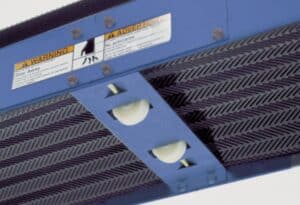

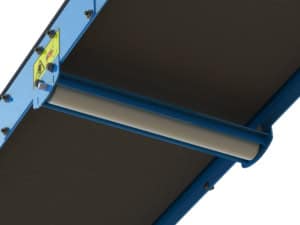

RETURN WHEELS / RETURN ROLLERS

Return wheels or return rollers carry belt on return bottom reducing friction and providing a longer belt life. It also puts less strain on the drive system.

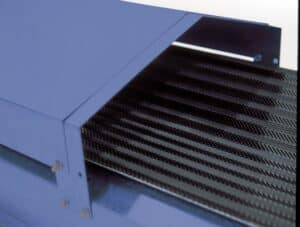

OPEN PAN DESIGN

Open pan design provides for extra capacity and reduces belt friction for lower power requirements. Fin pulley helps reduce material build-up for better belt tracking.

PRECISION BEARINGS

Precision bearings are sealed and greasable, ensuring long-life and trouble-free, continuous duty.

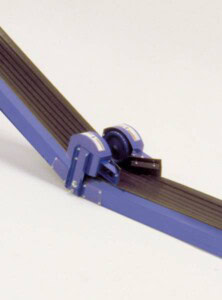

BELT TENSION ADJUSTMENT & TRACKING

Conveniently adjust belt tension and tracking. A 5/8″ screw provides up to 20″ of belt take-up. The pulley is finned for clean-out.

DECLINE / INCLINE ELBOWS

Elbows increase flexibility and permits elevation change without additional motors.

COVERS

Covers (optional) can help protect your conveyor and materials from rain, wind, and contaminants.

DRIVES

Drive Pulley, the standard drive, is crowned, steel and rubber lagged. Other drive options include: Electric and hydraulic.

Contact Your Representative

IA, IL, IN, KS, Lower MI,

MO, NE, Eastern WI

Kevin Habeck

Phone: 920-362-3261

Email: [email protected]

Find your Patz Rep

[display-map id=”4042″]